FLOW-GENIX globe valve is used for throttling flow control. Shut off is accomplished by moving the disc against the flow stream rather than across it as in the case with a gate valve. The flow pattern through a globe valve involves changes in direction, resulting in greater resistance to flow, causing the high-pressure drop. The globe valve is an excellent valve to use for on-off service, but is highly suited for frequent cycling and control of fluids anywhere in amount or volume between the open and closed positions.

FLOW-GENIX globe valve must be installed in the proper relation to the media flow as indicated by the flow direction arrow marked on the valve body. This valve is considered uni-directional and must be installed with the pressure side or inlet under the seat.

Our Globe Valves are generally supplied with manual hand lever or gear operated, depending on valve size. We are also offering Globe Valves with Pneumatic, Hydraulic or Electrical actuator operated for automation as per client’s requirement.

+91-96622 52502info@flowgenixvalves.com

| Valve Design | BS 1873 / ASME B 16.34 |

| Ins. & Testing | BS 6755 – II / API 598 |

| Face To Face | ASME B 16.10 / ND-40 |

| Flange Drilling | ASME B 16.5 / BS 10 Table / DIN / IS 6392 |

| Butt Weld End | ASME B 16.25 |

| Inspection | 3rd Party / Client / Manufacturer |

| Size Range | 50 NB through 400 NB (2″ to 16″) |

| Pressure Rating | ASME - 150#, 300#, 400#, 600#, 900#, 1500#, 2500# |

| Type | OS & Y, Bolted / Pressure Seal / Seal Welded Bonnet |

| End Connection | Flanged / Butt Weld / RTJ |

| Operation | Hand Wheel / Gear Operator / Electrical Actuator |

| Port Opening | Full |

| Seat | Integral / Renewable / Weld Deposited |

| Disc | Swivel - Flat / Taper / Control / Parabolic |

+91-96622 52502info@flowgenixvalves.com

+91-96622 52502info@flowgenixvalves.com

+91-96622 52502info@flowgenixvalves.com

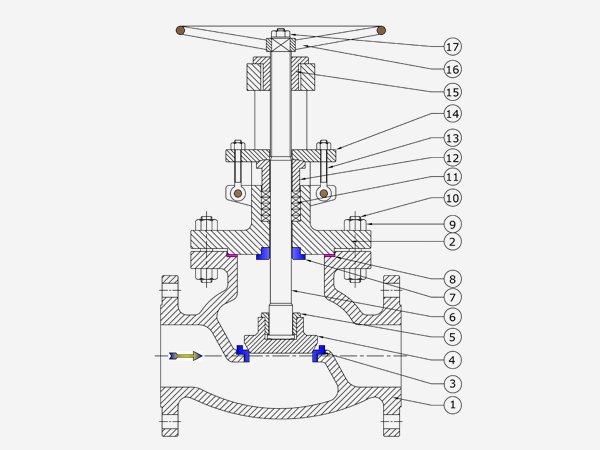

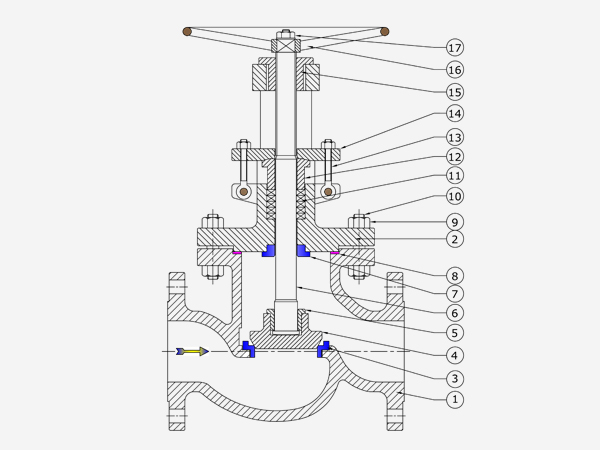

| SR. NO | PART NAME | MATERIAL |

| 1 / 2 | Body / Bonnet | ASTM A 216 Gr. WCB |

| ASTM A 217 Gr. WC1 / WC6 / WC9 / WC11 | ||

| ASTM A 352 Gr. LCB / LCC | ||

| ASTM A 351 Gr. CF8 / CF8M / CF3 / CF3M / CN7M / CF8C | ||

| IS 210 Gr. FG 200 / 220 / 250 / 260 | ||

| 5 / 6 / 7 / 12 | Trims (Working Parts) | AISI 410 (13% Cr.) / AISI 304 / 316 / 304L / 316L / Alloy 20 |

| 3 / 4 | Seat Ring / Disc | AISI 410 / ASTM A 217 Gr. CA15 / WCB + 13% Cr. Facing |

| 8 / 11 | Gasket & Gland Packing | PTFE / Graphite / Spiral Wound / Ring Joint |

| 14 | Gland Flange | M.S / C.S |

| 15 | Yoke Bush | M.S / ASTM A439 Gr.D2 / Gun Metal |

| 9 / 10 / 13 / 17 | Studs & Nuts / Eye-Bolts | ASTM A 193 Gr. B7 / A 194 Gr. 2H |

| S.S. 304 / 316 / 304L / 316L & Alloy Steel | ||

| 16 | Hand Wheel | Ductile Iron / S.G. Iron / Carbon Steel |

+91-96622 52502info@flowgenixvalves.com

+91-96622 52502info@flowgenixvalves.com

Copyright All Rights Reserved © 2022. Flow-Genix Valves & Controls Inc. || Powerd by - Prabhu Studio