FLOW-GENIX Gate valve is the most commonly used valve in the industry. Gate valves are well suited for water, oil, and gas service as well as a variety of other fluids. They are intended for on-off flow control and should only be used in the fully open or fully closed position. When fully opened, fluid through the valve is in a straight line, resulting in minimum pressure drop across the valve. Gate valves are bi-directional and can be used for flow in either direction.

Our manufacturing range also cover Half and Full Jacket Thermic Fluid Hot Oil Jacketed Gate Valve & Steam Jacketed Valve for sticky, viscous, molten Sulfur, bitumen, asphalt application. In full jacketed gate valve flange size will be higher than valve bore size. As like in 3″ (DN80) gate valve flange dimensions as per 4″(DN100), face to face distance as per ANSI B 16.10 Standard, valve size 3″(DN80).

Stellited trims are provided for all above 600# as a manufacturing standard of valves and in lower rating also on request. FLOW-GENIX also offer an extra-long, extended bonnet Gate valve for low temperature and cryogenic services. The antifriction thrust bearing is provided in the yoke sleeve for higher sizes and classes.

+91-96622 52502info@flowgenixvalves.com

+91-96622 52502info@flowgenixvalves.com

| Valve Design | BS 1414 /API 600 |

| Ins. & Testing | BS 6755 – II / API 598 |

| Face To Face | ASME B 16.10 |

| Flange Drilling | ASME B 16.5 / BS 10 Table / DIN / IS 6392 |

| Butt Weld End | ANSI B 16.25 |

| Pressure & Temperature Chart | ASME B 16.34 |

| Inspection | 3rd Party / Client / Manufacturer |

| Size Range | 50 NB through 900 NB (2″ to 36″) |

| Pressure Rating | ASME - 150#, 300#, 400#, 600#, 900#, 1500#, 2500# |

| Type | OS & Y, Bolted / Pressure Seal Bonnet / Seal Welded Bonnet etc. |

| End Connection | Flanged / RTJ / Butt Weld |

| Operation | Hand Wheel/ Manual Gear / Electric Motor Actuator |

| Port Opening | Full |

| Seat | Integral / Renewable / Seal Welded |

| Wedge | Solid / Flexible / Dual Disc |

| Gasket & Packing | PTFE / Graphite / Spiral Wound / Ring Joint |

+91-96622 52502info@flowgenixvalves.com

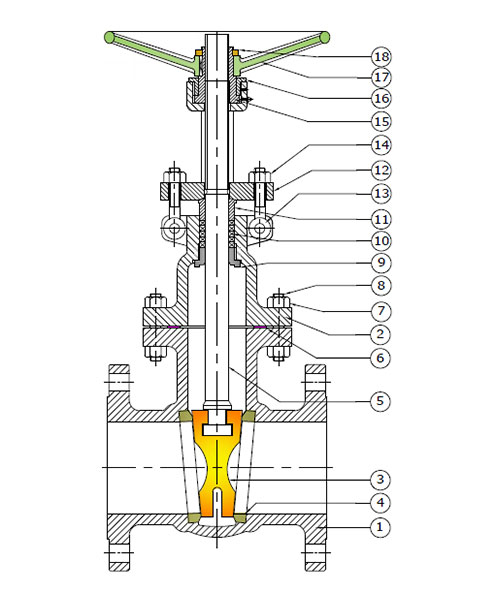

| SR. NO | PART NAME | MATERIAL |

| 1/2/3 | Body / Bonnet / Wedge | ASTM A 216 Gr. WCB |

| ASTM A 217 Gr. WC1/WC6/WC9/WC11 | ||

| ASTM A 352 Gr. LCB/LC3 | ||

| ASTM A 351 Gr. CF 8 /CF 8M/CF 3/CF 3M/CN 7M | ||

| IS 210 Gr. FG 200/220/250/260 | ||

| 4/5/9/11 | Trims (working parts) | AISI 410 (13% Cr.)/AISI 304/316/304L/316L/Alloy 20 |

| 15 | Yoke Sleeve | C.S./ASTM A439 Gr. D2/Gun Metal |

| 12 | Gland Flange | M.S/AISI 304/316/304L/316LS |

| 10 | Gland Packing | Grafoil / Graphite Asbestos / P.T.F.E. “V” Ring |

| 6 | Gasket | CAF / Grafoil /S.S. Spiral Wound With CAF /Grafoil / P.T.F.E. |

| 7/8/13/14/16/18 | Bolts / Stud & Nuts | ASTM A 193 Gr. B7 / A 194 Gr. 2H |

| S.S. 304 / 316 / 304L / 316L | ||

| 17 | Hand Wheel | Ductile Iron / S.G. Iron / Carbon Steel |

+91-96622 52502info@flowgenixvalves.com

+91-96622 52502info@flowgenixvalves.com

+91-96622 52502info@flowgenixvalves.com

Copyright All Rights Reserved © 2022. Flow-Genix Valves & Controls Inc. || Powerd by - Prabhu Studio