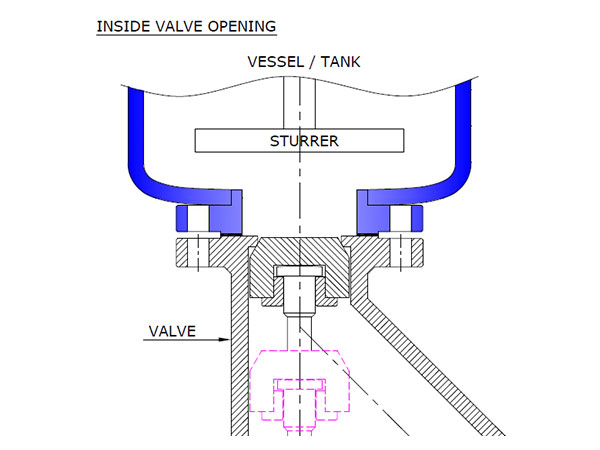

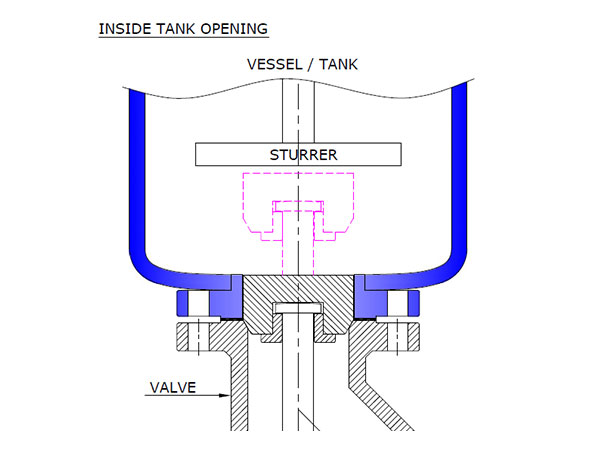

FLOW-GENIX Flush bottom valves (referred to as Tank valve, Angle bottom valve, Bottom drain valve, Flush mount valve, etc.) are designed to provide drainage and dead space free shutoff for reactors, vessels, autoclaves, and storage tanks. The dead space free shutoff is accomplished by placing the valve seat flush with the bottom of the vessel. This eliminates any buildup of product within the vessel nozzle itself.

FLOW-GENIX Provide Casted and fabricated in all available metallurgy, Carbon Steel, S.S 304, S.S 316, S.S 304L, S.S 316L, Alloy 20, Hast alloy, and as per special specifications. Conical Metal to Metal disc seating/ PTFE seating with option of fixed or Renewable seat. Further metal seating can be hard faced by Satellite TM where distortion of seat by aggressive liquid or slurry is common.

Generally Flush Bottom Ball Valve body is modified by adding Inlet oversize flanges. For an example: 2″ x 3″ Flush Bottom Ball Valve has the nominal bore of 2″ (DN 50), the Inlet flange (Vessel Side) size is 3″(DN 80), and outlet flange size 2″. It allows enough space for bolting clearance & insulation at vessel bottom flange.

+91-96622 52502info@flowgenixvalves.com

| Design | Manufacturing Standard |

| Testing & Inspection | Manufacturing Standard |

| Ends Connections | Flanged End |

| Flange Drilling | ANSI B16.5 |

| Size Range | 1.5″ to 24″ |

+91-96622 52502info@flowgenixvalves.com

+91-96622 52502info@flowgenixvalves.com

+91-96622 52502info@flowgenixvalves.com

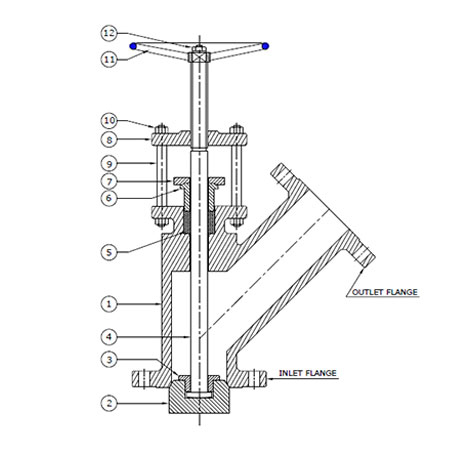

| 1 | Body | ASTM A 216 Gr. WCB |

| ASTM A 351 Gr. CF8 / CF8M / CF3 / CF3M | ||

| M.S / S.S 304 / 316 / 304L / 316L (Fabricated) | ||

| 2 | Disc | AISI 410 / S.S 304 / 316 / 304L / 316L |

| 3 | Disc Nut | AISI 410 / S.S 304 / 316 / 304L / 316L |

| 4 | Stem | AISI 410 / S.S 304 / 316 / 304L / 316L |

| 5 | Gland Packing | P.T.F.E / Graphoil |

| 6 | Gland Bush | AISI 410 / S.S 304 / 316 / 304L / 316L |

| 7 | Gland Flange | AISI 410 / S.S 304 / 316 / 304L / 316L |

| 8 | Pillar Flange | AISI 410/ S.S 304 / 316 / 304L / 316L |

| 9 | Pillar | AISI 410 / S.S 304 / 316 / 304L / 316L |

| 10 | Pillar Nut | C.S / 2H / S.S |

| 11 | Hand Wheel | S.G.I / D.I / M.I |

| 12 | Hand Wheel Nut | C.S / 2H / S.S |

Flush Bottom Tank Valve

(Gear Operated)

Flush Bottom Tank Valve

(Pne. Cyli. Ope. With Manual Arrangement)

Jacketed Flush Bottom Tank Valve

Copyright All Rights Reserved © 2022. Flow-Genix Valves & Controls Inc. || Powerd by - Prabhu Studio