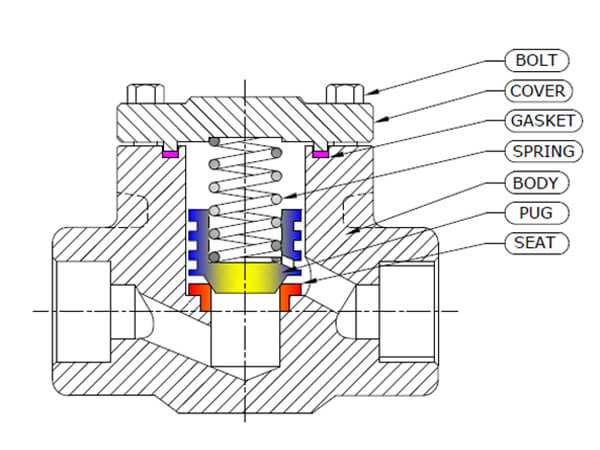

FLOW-GENIX Forged Steel Lift Check Valve, in common with all check valves, are used to prevent backflow in the line, and operate automatically, according to increases or decreases in line pressures. Flow through a lift check is the same as a globe valve. The disc raises up off of the seat as pressure below the disc increases, while a drop in pressure on the inlet side and a build-up of pressure on the outlet side causes the valve to close. Backpressure in the line holds the disc in the closed position.

Lift check valves are generally installed in a horizontal flow, but may be installed in vertical lines with the assistance of a spring behind the disc. The lift check valve in its closed position offers a more effective shutoff and tighter seal than the Swing Check.

For High Pressure & Temperature application, Stellited F6 Face Seat & Disc available.

For Flanged End Forged Steel Lift Check Valve flanges will be welded with a valve body not integral forged.

Lift Type Check Valve also can available with Spring Loaded version on specific requests.

+91-96622 52502info@flowgenixvalves.com

| Valve Design | BS 5352 / API 602 / ASME B 16.34 |

| Ins. & Testing | API 598 |

| Face To Face | ASME B 16.10 |

| Flange Drilling | ASME B 16.5 |

| Butt Weld End | ASME B 16.25 |

| Socket Weld End | ASME B 16.11 |

| Screwed End | ASME B 1.20.1 (BSP / NPT) |

| Pressure Rating of Valve | 800# / 1500# |

| Valve Seat Leakage | Leakage Class IV (For metal to metal seated valves) |

| Size Range | 1/2″ to 2″ |

+91-96622 52502info@flowgenixvalves.com

| Body & Cover | ASTM A 105 / ASTM A 182 F 304 / 316 / 304L / 316L |

| ASTM A 182 F 11 / F 22 | |

| Seat | AISI 410 / 304 / 316 / 304L / 316L etc. |

| Plug | AISI 410 / 304 / 316 / 304L / 316L etc. |

| Spring | Spring Steel / S.S. |

| Gasket | S.S SPW With CAF / P.T.F.E / Graphite |

| Bolts | ASTM A 193 Gr. B7 & S.S. 304 / 316 / 304L / 316L |

Copyright All Rights Reserved © 2022. Flow-Genix Valves & Controls Inc. || Powerd by - Prabhu Studio